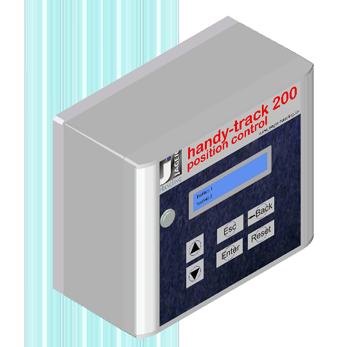

handy-track 200 position control unit

| item no. | designation | suitable for position measuring systems | additional equipment | image | weight [kg] |

|---|---|---|---|---|---|

| 60455 | handy-track 200 | RS232 and RS422 | mounting bracket to customers peripherie |  |

4.9 |

- microprocessor based system with dual line alpha numeric display

- simple and intuitive operation via the keypad and LC- display

- tightening sequence programmable by 'teach in' process

- with Laptop and ht200soft or keypad teachable.

- release of the tool only then, when the nutrunner is in the teached fishing range

- fishing range for each tightening position separately adjustable

- 2D- or 3D-analysis depending on the entailed mechanic

- allocation of a definite name for each work piece by the operator possible e.g. flange001

- control of different tool parameters via digitally in- and outputs (24V)

- integration into an automated system via digital input

- provision of a total IO/NIO signal for the PLC/nutrunner controller

- selection of max. 127 work pieces with each 33 tightening positions with:

- ht200- operator panel

- extern PLC

- binary selector switch - preparation of a signal for the line controller if the tool is in the home position

- back-up will be safed in a external process data memory

- supply voltage 230V AC

- user language: german/englisch - switchable

- documentation: german and englisch

-

links and signals:

- incremental encoder: max. 2 pieces

- distance sensor max. 1 piece

- input signal 24V: 2 (optional 3), e.g. work piece in position, tool in home position

- output signal 24V: 2 (optional 3), e.g. work piece clamping

- reference point reset with extern signal e.g. with index appliance pin

Not in scope of supply:

- controller cable from handy-track 200 to customers sides PLC/nutrunner cotroller- encoder cable for connection rotary encoder with handy-track 200